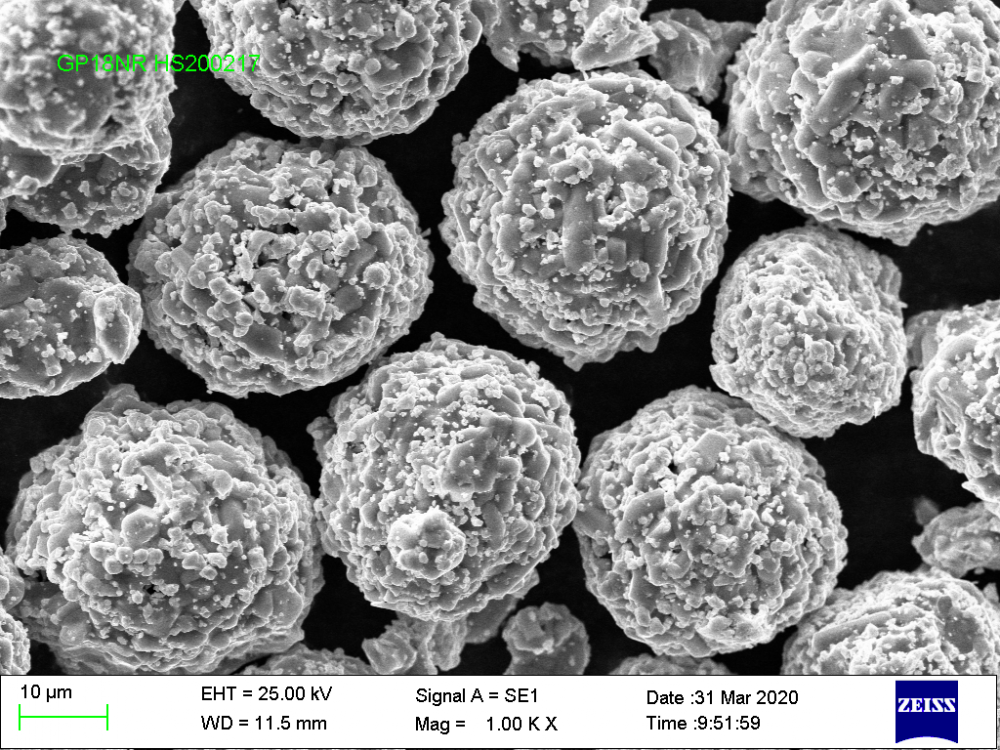

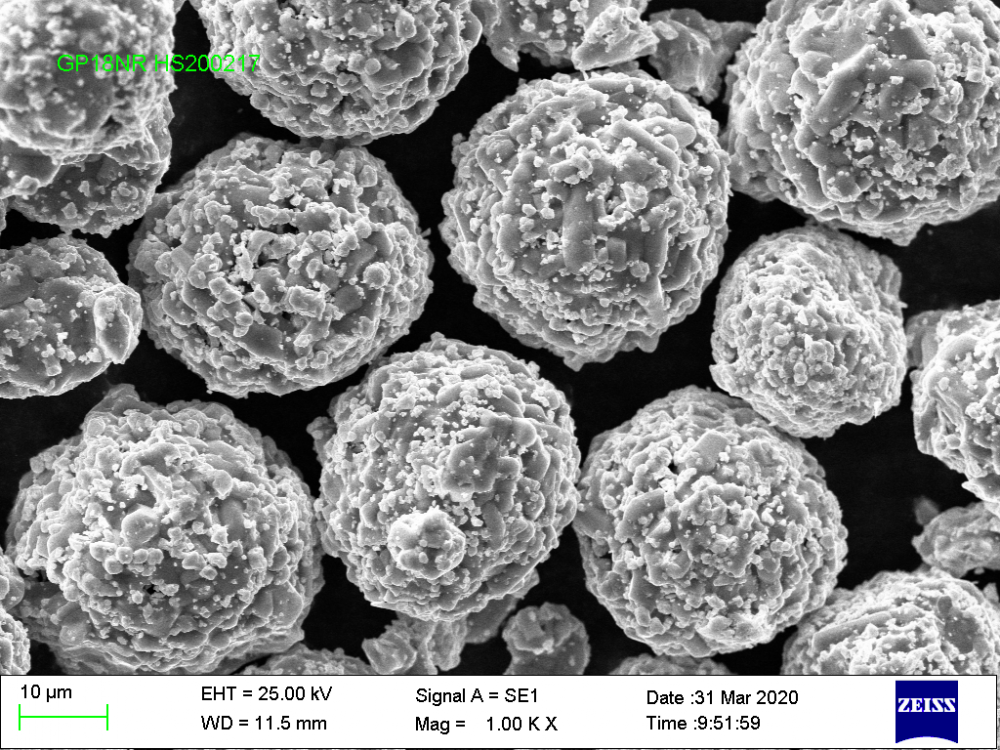

Excellent decay resistance performance in Coating, Cr3C2-37WC-18NiCoCr , 15-45um Tungsten Carbide Powder is generally used in High Velocity Oxygen Fuel (HVOF) spray. Comparing with chromplate, it provide the coating with environmental solution. This powder can offer Tungsten Carbide Coating a higher hardness and better wear resistance due to Tungsten Carbides composition in it.The applications are hydraulic rod repair,pump rod repair,valve parts repair, , and steel rollers repair etc. The manufacturing process is Agglomerated and Sintered which can bring HVOF Tungsten Carbide Coating a better deposit efficiency and micro-hardness.

Thermal Spray Cr3C2-37WC-18NiCoCr Powder 15-45um refers to a specific type of powder used in thermal spray processes.

- Cr3C2-37WC-18NiCoCr: This composition refers to the materials used in the powder. It consists of chromium carbide (Cr3C2), tungsten carbide (WC), nickel (Ni), cobalt (Co), and chromium (Cr). These materials are chosen for their high melting points, wear resistance, and corrosion resistance properties.

- Powder: The material is in powder form, which is commonly used in thermal spray processes. The powder particles have a size range of 15-45 micrometers (um), meaning they have diameters between 15 and 45 micrometers.

Thermal spray is a coating process where the powder material is heated and propelled onto a surface to create a protective or functional coating. In this case, the Cr3C2-37WC-18NiCoCr powder is likely used to create a coating that provides wear resistance, corrosion resistance, and high-temperature protection to the substrate material.

Spray System HVOF

Coating Micro-hardness 850-1150 HV0.3

Bonding Strength ≥70MPa

Porosity <1%

Deposit Efficiency 45-60%

Maximum Service Temperature 870℃

Product Categories : Thermal Spray Materials > Tungsten Carbide Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now