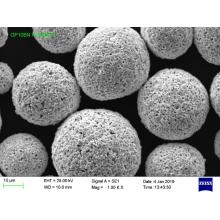

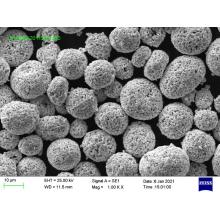

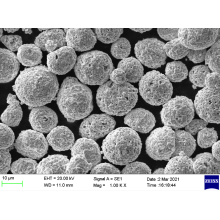

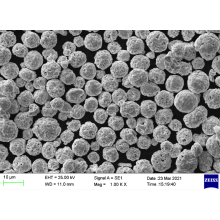

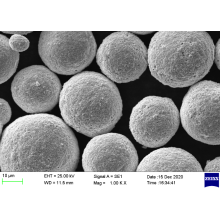

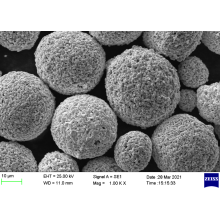

WC-13Co Tungsten Carbides 45-150um Tungsten Carbide Powder with inrregular Size mainly for Centrifugal Casting Tungsten Carbide Coating.

Sintered and Crushed, using coarse WC

Carbon content: 4.0%-4.5%

Apply to extruder barrel of the injection molding machine and mining industry to strengthen the surface of the mechanical parts to extend their service life and improve the hardness and abrasion resistance

Spray System APS, HVOF Tungsten Carbide Coating

Coating Micro-hardness 950-1200 HV0.3

Bonding Strength ≥70MPa

Porosity <1%

Deposit Efficiency 50-80%

Maximum Service Temperature 500℃

WC-13Co Tungsten Carbides 45-150um Tungsten Carbide Powder with inrregular Size mainly for Centrifugal Casting Tungsten Carbide Coating.

Sintered and Crushed, using coarse WC

Carbon content: 4.0%-4.5%

Apply to extruder barrel of the injection molding machine and mining industry to strengthen the surface of the mechanical parts to extend their service life and improve the hardness and abrasion resistance

Spray System APS, HVOF Tungsten Carbide Coating

Coating Micro-hardness 950-1200 HV0.3

Bonding Strength ≥70MPa

Porosity <1%

Deposit Efficiency 50-80%

Maximum Service Temperature 500℃

Product Categories : Thermal Spray Materials > Tungsten Carbide Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now