News

News

Introduction of Thermal Spray Powder For Corrugator Roll

2022-05-07

Thermal spray is a new technology of surface strengthening and protecting, is a great part of surface modification. As the development of science and technology, thermal spray technology has obtained extensive promotion and application on strengthening wear resistance of papermaking corrugator roll tooth surface. Corrugator roll is the core part of paperboard production line, it is a continuous wearing process of using it. it costs a lot to recover the surface of these parts. Recovering corrugator roll through thermal spray technology is more economic and will greatly extend service life of rolls, and could reach 3-6 times of Chromium plated layer.

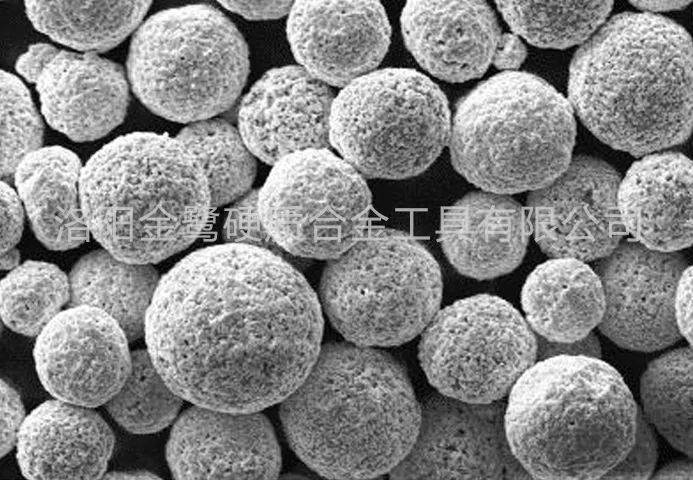

Thermal Spray Powder suitable for papermaking corrugator roll of Luoyang Golden Egret is mainly two kinds: WC-12Co and WC-10Co-4Cr series. The powder is consistent in composition and has a concentrated particle size distribution, stable apparent density, high sphericity. Spraying WC based powder on the surface of corrugator roll could form a coating with high hardness, great wear resistance, low porosity and low surface roughness, strongly increases the work life of corrugator rolls, lower the cost of surface treatment, which is more economic.

01. Product Series

WC-12Co: GP12-2 (15-38um, apparent density 4.3-5.0g/cm3)

GP12U-19 (5-30um, apparent density 4.7-5.6 g/cm3)

WC-10Co-4Cr: GP10CU-19 (5-30um, apparent density 5.0-6.2/cm3)

GP12-2 GP12U-19 GP10CU-19

02. Coating Performance

The coating performance is excellent applied with HVOF, details as follows:

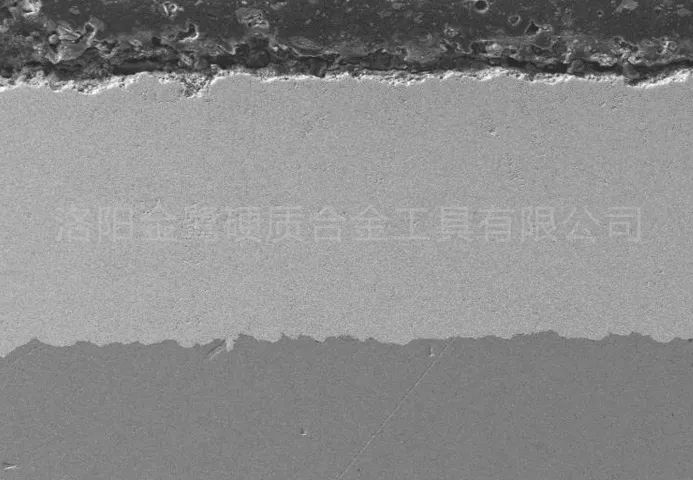

1) Metallographic Structure

Dense coating, great bonding with matrix, oxide is unseen, WC particles are distributed evenly.

2) Porosity

Porosity is less than 0.3%

3) Bonding Strength

Bonding strength is greater than 70MPa

4) Micro Hardness

Micro harness test press of coating is good, no subside, the hardness is consistent

WC-12Co HV0.3 1100-1200

WC-10Co-4Cr HV0.3 1100-1250

WC-20Cr3C2-9Ni HV0.3 1000-1200

5) Coating Corrosion Resistance

Under standardized salt spray test, no obvious corrosion trace appeared after 240H.

03. Application

WC-12Co series:

GP12-2: Medium WC used, with great wear resistance and impact resistance, mainly applied to corrugator roll carton machinery, single facer, suitable for A/B/C corrugator type.

GP12U-19: Fine WC used, more dense coating , lower surface roughness, recommended for E/F corrugator type, offers great hardness and wear resistance of coating.

WC-10Co-4Cr series:

GP10CU-19: Fine WC used, with great wear resistance and corrosion resistance, dense coating with lower surface roughness, mainly applied to A/B/C corrugator type, offers great hardness and wear resistance of coating.