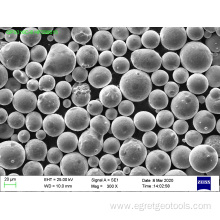

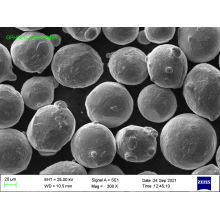

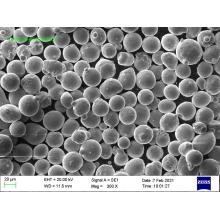

These hard phases are comprised of complex bi- and tri- metallic borides and carbides, which are precipated during manufacturing, and are an inherent part of the microstructure and not added externally as in conventional composite powders. The hard phases remain uniformly distributed during shipping, spraying, and fusing to ensure consistent performance throughout the coating and will not erode prematurely. The hard phases, along with the high-hardness Ni-Cr-B matrix, resist extreme abrasion and corrosion, GPNiW15 can be spray deposited and fused to achieve a hardness range of Rockwell hv 59-64.

Chemical Composition Of Powder:

Ni:Bal

W: 17.3

Cr: 15

Fe:3.5

Si:4

B: 3

O: 0.05

C: 0.8

Company product profile:

Luoyang Golden Egret Geotools Co.,Ltd. founded in2012,is wholly-owned by iisted company XiamenTungsten Co.,Ltd (XTC).As a backbone cemented carbideenterprise of XTC with registered capital of 1.05billionRMB and first investment of ibillion RMB,GEOTOOLSspecializes in producing and selling high quality tungstenpowder,

Tungsten Carbide Powder, carbide anvils,carbideroll rings,carbidesubstrates for PDC bit,mining drill bitsand hard facing materials.

Based on decades of production experience of WC based hard-facing materials, world-class technologies and modernautomatic production lines, GEOTOOLS dedicates into development and production of high quality hard facing materialwith high hardness, best wear resistance, best corrosion resistance and application solutions.

XTC brand

Thermal Spray Powder mainly includes Wc- based & Cr3C2-based. The WC coating has high hardnessdurable wear resistance, abrasion resistance, corrosion resistance and high bonding strength, mainly used in oil &gas valves, mining tools, injection screws and printing machinery parts, The Cr3c2 coating has higher thermalstability and anti-oxidation, which can be used in a high temperature and corrosive environment, e.g. inner- wall ogas pipeline and pump.

With high degree of sphericity & excellent alloy organization, cemented carbide pellet is mainly used in weldingas an additive material of

PTA Powder and tubular weldina rod to improve the wear resistance of the work pieces.

GEOTOOLS provides mono-crvstalline WC-based, coarse-arain wC-based, casting WC-based and other kinds ofPTA powder. With the high quality material, most advanced production lines and word-class technologies, the PTAcoating has high hardness, durable wear resistance, high welding velocity, and low porosity characteristics. Mainlyused in Mining, Oil driling, agriculture machinery, and machining for welding and repairing.

The hard phase of GEOTOOLS tube rods is tunasten or its products with high wear resistance. Tubular welding rods aresuitable for flame brazing and widely used for surface strengthen for oil and mining drill bits.

In general, the combination of nickel-based alloys with tungsten carbide powder can create a new material with both good corrosion resistance and excellent hardness and wear resistance, which is very valuable for many industrial applications.

Product Categories : Laser Cladding Powder > Nickel Alloy Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now