Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Luoyang Golden Egret Geotools Co., Ltd

- [Henan,China]

- Business Type:Manufacturer

- Main Markets: Worldwide , Americas , Asia , East Europe , Europe , Middle East , North Europe , Oceania , Other Markets , West Europe

- Exporter:41% - 50%

- Certs:ISO14001, ISO9001, MSDS, Test Report

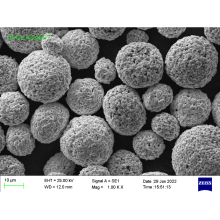

- Description:Gate Valve Coating Powder,Corrugated Roller Coating,Valve Coating Powder

Contact Now

Contact Now

Contact Now

Contact Now